Introduction to 3D Laser Scanning: What It Is and Why It Issues

What Is 3d Laser Scanning Technology .3D laser scanning is a transformative innovation that has actually changed the method we capture and analyse the physical world. From industrial design to heritage conservation, this modern technology supplies an accurate and effective way to create detailed digital models of items, buildings, and landscapes. In an increasingly digital age, understanding the fundamentals of 3D laser scanning is crucial for sectors and specialists looking for to remain in advance of the curve. This post provides an extensive introduction to 3D laser scanning, discovering what it is, why it matters, and the different means it is being made use of across various markets.

What Is 3D Laser Scanning?

At its core, 3D laser scanning is a modern technology that captures the form of physical objects using laser light. It works by emitting laser beam of lights that jump off surfaces and go back to the scanner, which after that computes the distance based upon the time it takes for the light to return. This process, referred to as time-of-flight dimension, permits the scanner to create specific three-dimensional representations of the scanned things or atmosphere.

These depictions are usually described as factor clouds, which are thick collections of information points in a three-dimensional coordinate system. Each factor in the cloud represents an exact location externally of the checked item, capturing not only its form but likewise its appearance and colour (depending on the type of scanner used). When recorded, these factor clouds can be processed and exchanged 3D versions utilizing specialised software.

The Elements of a 3D Laser Scanner

A common 3D laser scanner consists of a number of crucial components:

-

Laser Emitter: This part creates the laser beam that is forecasted onto the things or surface being scanned.

-

Receiver/Detector: The receiver finds the laser light as it mirrors back from the things. It measures the moment taken for the light to return, which is after that used to compute the distance between the scanner and the object.

-

Rotating Mirror: In lots of scanners, a rotating mirror is made use of to direct the laser beam of light across the things. This allows the scanner to catch information from different angles, making certain that the whole surface area of the object is covered.

-

Control System: The control system takes care of the procedure of the scanner, consisting of the timing of the laser pulses and the motion of the turning mirror.

-

Data Processing Software Program: Once the raw data is collected, it needs to be processed right into a useful style. Specialised software program is made use of to convert the point cloud information into a 3D model, which can after that be evaluated, changed, or incorporated right into various other electronic systems.

Sorts Of 3D Laser Scanners

There are numerous types of 3D laser scanners, each matched to various applications:

-

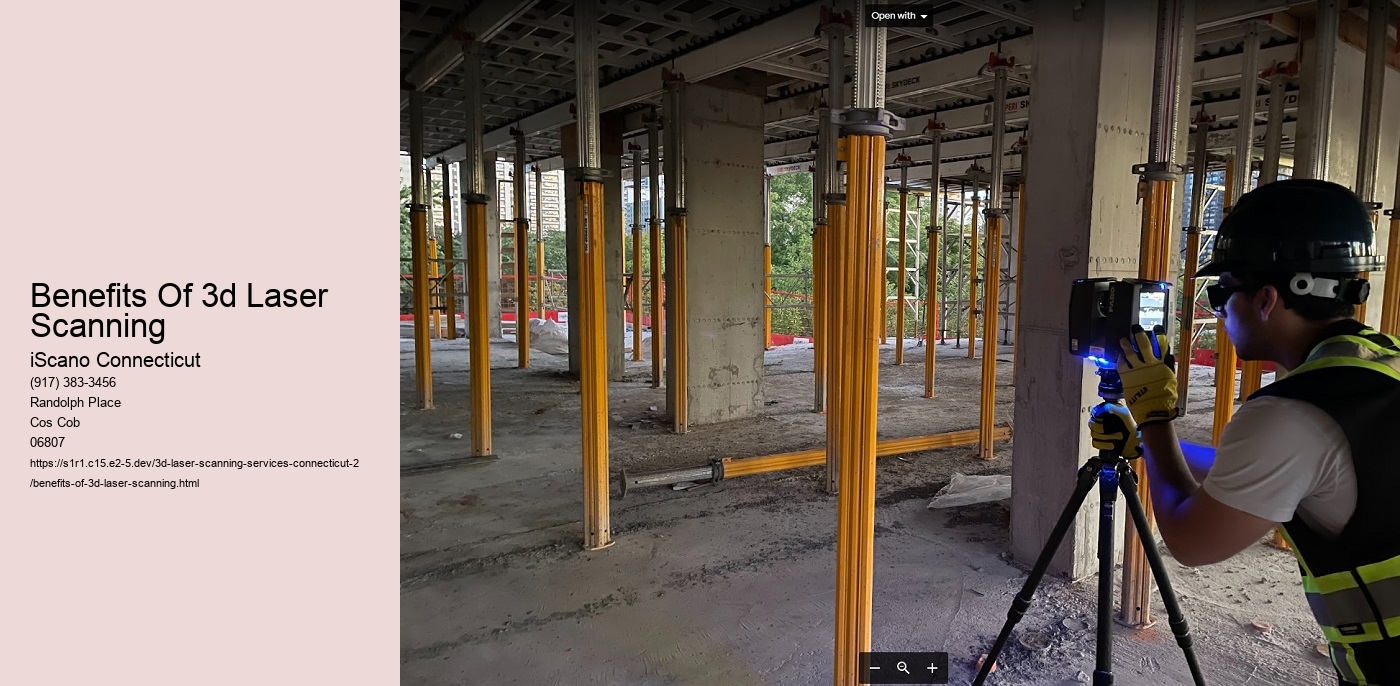

Terrestrial Laser Scanners (TLS): These scanners are usually made use of for large tasks such as checking buildings, bridges, or landscapes. They are placed on a tripod and can catch information from cross countries, making them suitable for outside usage.

-

Handheld Laser Scanners: As the name recommends, these scanners are mobile and can be utilized to capture smaller sized things or locations that are tough to get to with a larger scanner. They are generally used in sectors such as automobile, aerospace, and manufacturing.

-

Aerial Laser Scanners (LiDAR): LiDAR (Light Detection and Ranging) is a type of laser scanning that is normally placed on aircraft or drones. It is utilized to record massive topographical data, such as forests, mountains, or urban areas.

-

Structured Light Scanners: Unlike typical laser scanners that make use of a single laser beam of light, structured light scanners forecast a pattern of light onto the item. By evaluating the contortion of the pattern, the scanner can create a 3D model. These scanners are frequently used for comprehensive evaluations in manufacturing and quality control.

Why 3D Laser Scanning Issues

The value of 3D laser scanning lies in its ability to offer extremely precise and thorough depictions of the physical world. This capacity has far-reaching implications throughout numerous industries and applications:

-

Accuracy and Accuracy: 3D laser scanning can record numerous data factors per 2nd, resulting in highly detailed and accurate versions. This degree of accuracy is essential in markets such as design, design, and construction, where even small mistakes can have significant repercussions.

-

Efficiency: Typical techniques of dimension and documents can be time-consuming and labour-intensive. 3D laser scanning simplifies the process by recording thorough information in a portion of the moment. This efficiency is especially useful in massive projects, such as evaluating a building website or documenting a historic spots.

-

Non-Invasive Information Collection: 3D laser scanning is a non-contact method, meaning that it does not require physical communication with the things being scanned. This is specifically vital when taking care of delicate or inaccessible items, such as cultural heritage websites, archaeological artefacts, or hazardous settings.

-

Flexibility: 3D laser scanning is a flexible modern technology that can be used in a wide variety of markets, from manufacturing and building to healthcare and enjoyment. Its capability to record intricate geometries makes it important in any field that needs comprehensive spatial evaluation.

-

Improved Visualisation and Analysis: The 3D models created by laser scanning can be made use of for visualisation, simulation, and analysis. For instance, designers can use these versions to develop online walkthroughs of structures, while designers can imitate how a framework will certainly act under different problems.

Introduction of 3D Laser Scanning Technology

To understand the complete effect of 3D laser scanning, it's crucial to explore the modern technology behind it and how it has actually developed throughout the years.

The Evolution of 3D Laser Scanning

3D laser scanning has its roots in the early 1960s, when the first laser was created. Originally, lasers were used primarily for scientific study and armed forces applications. Nonetheless, as technology progressed, the capacity for utilizing lasers to measure ranges and capture thorough spatial data emerged.

In the 1980s, the very first commercial laser scanners were presented, noting a substantial turning point in the growth of 3D scanning technology. These very early scanners were large, pricey, and restricted in their capacities, but they prepared for future improvements.

The 1990s saw substantial renovations in laser scanning technology, with the introduction of more compact and affordable scanners. This period additionally saw the development of software program that might refine point cloud data into 3D designs, making the modern technology more accessible to a bigger variety of markets.

Today, 3D laser scanning is a mature technology that remains to evolve. Breakthroughs in calculating power, information storage, and software program algorithms have actually made it feasible to capture and refine bigger and much more complex datasets. At the exact same time, the growth of new scanning innovations, such as handheld and drone-mounted scanners, has actually broadened the series of applications for 3D laser scanning.

Trick Technologies in 3D Laser Scanning

Numerous essential modern technologies are essential to the procedure of 3D laser scanners:

-

Time-of-Flight (ToF) Dimension: This is one of the most usual method utilized in 3D laser scanning. It entails determining the moment it considers a laser beam to take a trip to a things and back to the scanner. By determining the time-of-flight, the scanner can identify the distance to the object and create a 3D factor.

-

Stage Shift Measurement: In phase shift dimension, the scanner releases a continual laser beam of light that is regulated in amplitude. The phase distinction between the produced and received light is used to determine the range. This method is typically used in high-precision scanners and can achieve higher precision than time-of-flight measurement.

-

Triangulation: Triangulation-based scanners utilize a laser beam and a video camera to record information. The laser predicts a point or line onto the item, and the camera records the reflected light. By evaluating the angle between the laser, the things, and the video camera, the scanner can figure out the distance and produce a 3D point.

-

Structured Light: Structured light scanners forecast a pattern of light (such as stripes or dots) onto the things. The contortion of the pattern is caught by a cam, and the data is utilized to calculate the 3D form of the object. Structured light scanners are recognized for their high accuracy and are often utilized in applications calling for thorough surface area measurements.

-

Multi-Sensor Combination: Some innovative 3D laser scanners integrate numerous sensing units, such as cams, GPS, and inertial measurement devices (IMUs), to improve the accuracy and convenience of the data. As an example, LiDAR systems made use of in autonomous vehicles often integrate laser scanning with other sensors to create a thorough map of the setting.

Applications of 3D Laser Scanning

The applications of 3D laser scanning are large and varied, with the modern technology being made use of in numerous industries:

-

Style and Building And Construction: 3D laser scanning is extensively used in the style and construction markets to develop exact as-built designs of structures and facilities. These models can be utilized for style, restoration, and upkeep functions, as well as for clash detection in complex jobs.

-

Manufacturing: In manufacturing, 3D laser scanning is utilized for quality control, reverse engineering, and prototyping. The ability to catch precise dimensions of parts and assemblies makes sure that products satisfy layout requirements and feature as planned.

-

Social Heritage and Archaeology: 3D laser scanning plays a crucial role in protecting cultural heritage sites and artefacts. By developing detailed digital documents, researchers can examine and analyse these treasures without running the risk of damages. Furthermore, 3D designs can be used for virtual repair and visualisation, permitting the general public to experience archaeological sites in brand-new ways.

-

Healthcare: In health care, 3D laser scanning is used for a variety of applications, consisting of producing personalized prosthetics, orthotics, and dental home appliances. The innovation is additionally utilized in medical imaging and surgery planning, where precise 3D designs of clients' ' composition are crucial for effective end results.

-

Entertainment and Media: The show business has actually accepted 3D laser scanning for producing reasonable visual effects, computer animations, and virtual reality experiences. The modern technology allows filmmakers and video game designers to capture real-world settings and characters, bringing a new level of realistic look to their job.

-

Transport and Facilities: 3D laser scanning is used in transport and framework jobs to check roadways, bridges, tunnels, and railways. The data gathered can be made use of for preparation, design, and maintenance, making sure that these vital structures remain safe and functional.

-

Environmental Monitoring: LiDAR, a sort of 3D laser scanning, is commonly made use of in environmental monitoring and natural deposit management. It is made use of to map forests, action vegetation development, display coastal disintegration, and analyze the influence of natural calamities.

The Future of 3D Laser Scanning

As innovation continues to advance, the future of 3D laser scanning looks promising. A few of the key fads and growths that are most likely to shape the future of this modern technology consist of:

-

Increased Automation: The integration of artificial intelligence (AI) and machine learning right into 3D laser scanning systems will certainly allow greater automation in data collection and handling. This will lower the requirement for hand-operated treatment and increase the rate and performance of scanning operations.

-

Miniaturisation and Portability: As scanners lessen and more portable, they will be simpler to deploy in a larger range of settings. This will open new opportunities for applications in locations such as space exploration, disaster action, and wearable technology.

-

Real-Time Processing: Advances in computing power and information storage will certainly make it possible for real-time processing of point cloud data, permitting individuals to watch and evaluate 3D designs on the place. This will be specifically useful in industries such as building and surveying, where instant responses is necessary.

-

Integration with Various Other Technologies: The future of 3D laser scanning will likely entail greater integration with various other modern technologies, such as drones, robotics, and the Internet of Things (IoT). This will certainly allow much more detailed information collection and evaluation, bring about brand-new insights and applications.

-

Democratisation of 3D Scanning: As 3D laser scanning technology becomes a lot more budget friendly and easily accessible, it will certainly be adopted by a broader series of markets and specialists. This democratisation will certainly drive technology and broaden the use situations for 3D scanning, making it a crucial device in the electronic age.

Verdict

3D laser scanning is a powerful and flexible innovation that has changed the means we capture and evaluate the real world. Its capability to provide precise, thorough, and efficient dimensions has actually made it an indispensable device across a wide variety of industries, from construction and making to medical care and social heritage. As the technology remains to evolve, we can anticipate to see even higher improvements in automation, transportability, and assimilation, leading the way for brand-new applications and opportunities. Whether you're an engineer, architect, archaeologist, or filmmaker, understanding 3D laser scanning is essential for remaining in advance in an increasingly electronic world.